INCONEL ALLOY 625 IN AEROSPACE ENGINEERING

- September 22, 2023

- Posted by: vAchESpAVe388ema5hetray8

- Category: BSW blog EN

INCONEL alloy 625 and aerospace engineering are a great combination. Find out why in this blog exploring this essential high-performance nickel alloy

When INCONEL alloy 625 was first introduced in the early 1960s, the possibilities for how it could be used in the future were endless. While it might have been initially created for use in ultra-critical steam-line piping, experts in metallurgy foresaw its importance in seawater, aerospace and chemical processing applications. These predictions have come true, and INCONEL alloy 625 is now a staple material within the aerospace industry, among others.

Over time, processing methods have developed that have enabled this multitasking nickel alloy to firmly root its place as one of the most popular and versatile materials of choice for design engineers. For example, small changes to its composition and milling practises have increased its fatigue life as thin sheet, which has opened up new and exciting uses.

It’s not often that a particular alloy becomes a standard material of construction across so many different industries, which is testament to this alloy’s versatility. Over time, it has helped to solve many design challenges, and as industries have evolved, so has the list of possible applications for this wonder alloy.

KEY PROPERTIES FOR AEROSPACE APPLICATIONS

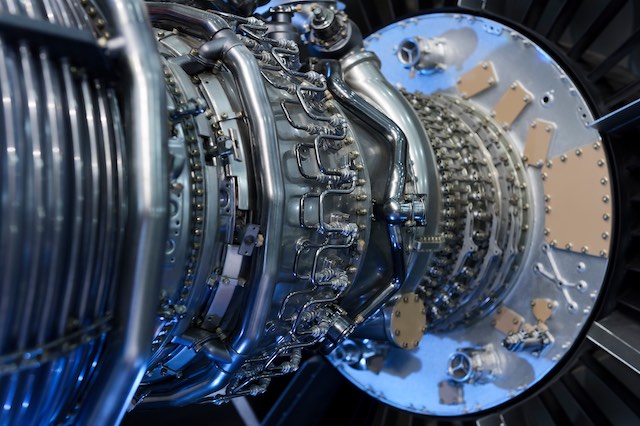

As the aerospace industry has modernised, expanded and developed, so too have the potential end uses of this high-performance alloy. Its unique microstructure lends the material an impressive set of properties and characteristics that make it indispensable. For a start, its exceptional corrosion resistance enables it to perform in a wide variety of extreme environments. Its ability to withstand high temperatures strengthens its usefulness in the high-pressure and hot conditions of a plane’s engine, for example. It’s no wonder that aerospace engineering and INCONEL alloy 625 go hand in hand.

Its chemical composition is also responsible for its use in aerospace applications. The inclusion of molybdenum alongside the nickel gives the alloy good resistance to non-oxidising environments, and makes it especially resistant against pitting and crevice corrosion. The small amount of niobium stabilises it against sensitisation during welding and prevents intergranular attack.

The niobium content also includes tantalum, a hard transition metal that is highly corrosion resistant and has a high melting point. The super combination in this alloy of nickel, chromium and molybdenum with niobium, helps to stiffen the alloy’s matrix and give natural high strength without a specific heat treatment.

CHOOSING SUPERALLOYS

INCONEL alloy 625 is known as a ‘superalloy’, or a high temperature alloy, which means that it has certain characteristics to earn the accolade. This includes its excellent mechanical strength, corrosion resistance, heat resistance, thermal creep deformation and surface stability. The term was first used just after World War II specifically to describe a group of alloys that were used in aircraft turbine engines that performed at the inherently high temperatures. Therefore ‘superalloys’ are very much grounded in aerospace, through the term is applied to many other applications such as gas turbines, rocket engines and chemical processing plants.

Superalloys retain good strength even after being exposed to temperatures above 650°C (1,200°F) for a long period of time. Combined with their ability to also exhibit low-temperature ductility and surface stability, it’s no wonder this group of high-performance alloys is considered ‘super’.

As nickel-based superalloys have so many advantages, they are key within the aerospace industry. This versatile group of metals would be hard to replace with any other material, while retaining the essential features that they are known for and their reliability for these high-performance tasks.

APPLICATIONS IN AEROSPACE

There are many potential uses for this technical alloy within aerospace, including aircraft ducting systems and jet engines. The actual list of applications is quite extensive, due to its versatility. Nickel alloys are selected across the board thanks to their high-temperature resistance, magnetic properties and corrosion resistance. They are also some of the toughest materials commercially available.

Jet engines present unique challenges for design engineers, as they are subject to extreme temperatures at both ends of the scale. At cruising altitude, the average outside air temperature is about -56.3°C (-74.7°F), while the actual combustion process can exceed temperatures of 1,150°C (2,120°F).

One of the primary applications of INCONEL alloy 625 in the aerospace industry is in an aircraft’s exhaust system. The materials used in these demanding exhaust systems must be durable, hard-wearing, tough and resistant to high temperatures. INCONEL alloy 625 may be found in use for tailpipes, vector nozzles, bellows and hush kits, among other key components.

One example of INCONEL alloy 625 being used for a key aircraft is in the United States Navy’s Prowler, as part of the CMX-124 tailpipe. The material was chosen for its excellent fatigue, strength and resistance to sensitisation.

A number of studies and research papers are available looking at INCONEL alloy 625 specifically within the aerospace industry. For example, in March 2018, a team of researchers published a paper in the International Journal of Material Forming looking at the ‘Mechanical properties and microstructure of INCONEL 625 cylinders used in aerospace industry subjected to flow forming with laser and standard heat treatment’.

The main aim of the experiment was to prepare manufacturing guidelines for aerospace industry requirements. At its conclusion, it found the optimum methodology to create a large hollow cylinder through laser heat treatment, proving that it was possible to get the right combination of strength and plasticity in cylindrical elements for aerospace applications. As more of these studies are published, the list of potential applications for this superalloy continues to increase.