Composition %

| CARBON - Max 0.03 | |

|---|---|

| CROM - Min 21 / Max 23 | |

| Fier - Balance | |

| MOLIBDEN - Min 2.5 / Max 3.5 | |

| MANGAN - Min - / Max 2 | |

| AZOT - Min 0.1 / Max 0.22 | |

| NICHEL - Min 4.5 / Max 6.5 | |

| FOSFOR - Min - / Max 0.04 | |

| SULF - Min - / Max 0.015 | |

| SILICIU - Min - / Max 1 |

General properties

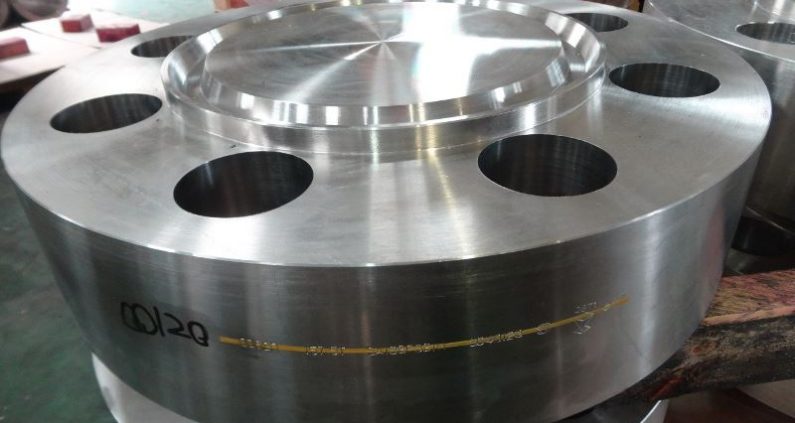

DUPLEX F51

UNS S31803 / W-Nr. 1.4462

Duplex F51 / UNS S31803 / W-Nr. 1.4462

“Duplex”-.-the material has a diphase microstructure made from grains from stainless steel ferrites and austenitic in the same material

“Super-Duplex”. It is duplex with better performance with a high percent of chrome and molybdenum. These elements increase the corrosion resistance pitting, and in the same time the contains of azote increase the yield strength.

Duplex and Super Duplex are in generally twice stronger than austenitic and ferrites stainless steel and have viscosity and ductility better than ferrites grades, and a better corrosion and stress resistance.

F51 has a better resistance at stress, corrosion comparing with stainless steel.F51 resist in cloric environment.

Typical applications: Oil and gas industry including pumps, valves, pipes, tubes, flanges, bolts, nuts and collectors.

Mechanical Properties

Tensile Strength (MPa /N/mm2 ) 655-880

0.2% Proof Stress (MPa /N/mm2 ) minimum 485

Elongation (A5 & 4D) minimum 25.00%

Reduction of Area minimum 45.00%

Hardness (HB) maximum 270

Charpy V-notch Impact at ambient Temp (J) 100 minimum

Charpy V-notch Impact at -46 deg C (J) 45 minimum

Ultrasonic Testing At customer’s request

Ferrite Content 35%-55%

Corrosion Test to ASTM G48 Method A 25 deg C for 24 hours

Microstructure certified free from grain boundary carbides, sigma, chi and laves phases